Vehicle owners are left ‘alone’ and have to be proactive in order to keep their vehicle in good conditions or to comply with contractual and governmental regulations to avoid any penalties.

For decades vehicle manufacturing companies did not perform innovative changes to enhance the customer experience throughout the vehicle lifecycle. However, today’s global market conditions and its ever-increasing competition in the markets, vehicle OEMs are forced to improve their services and hence the customer experience to sustain & gain market share and to differentiate from other competitors around the world.

Examples of improvements in terms of digitizing the customer journey through the vehicle lifecycle, such as digital applications to book service appointments, performing online payments and track on real-time the status of the vehicle repair are available nowadays, but still the customer journey is not seamlessly connected and does not offer an ‘all-round carefree package’ whereby the vehicle OEM takes over the responsibility and takes care of the customer needs pro-actively, for example, by monitoring the vehicle condition and driving behavior of the owner the OEM could ‘manage’ & suggest the owner products and services necessary to improve or maintain an optimal driving and owning experience.

We at Four Principles are truly convinced that by implementing Lean principles & methods combined with new technology available would significantly impact the OEM’s productivity, efficiency, cost and customer satisfaction.

Challenges

Automotive OEMs face several challenges while implementing innovative process changes to keep the customers loyal & satisfied throughout the vehicle lifecycle:

Establishing vehicle service logistics

Customers are expecting premium services such as vehicle pick-up, drop-off at preferred locations and a concierge service which is 24/7 available and takes care of any customer request

Improving vehicle service diagnostics

Vehicles lack built-in internet of things devices and mobile applications to deliver the manufacturer and customer with real-time information about the vehicle’s condition or required services to perform

Increasing vehicle services

Access to added services such as online payments, vehicle service bookings or real-time tracking on vehicle repair through inter of things are highly demanded by the customer, but are still not delivered by the automotive distributor

Enhancing continuous revenue engagement

To increase follow-on sales and to establish a long-term relationship with the customer, manufacturers are obliged to customize offers for each individual and advertise them through social media channels or OEM apps. Furthermore, cooperation with non-automotive companies can be established to provide more services to the customer

Improving customer usage experience

To improve the customer experience, OEMs have to offer a high range of customized options in their vehicles such as security, emergency, connectivity with 3rd party apps and features i.e. Apple Watch, Google Pay or Apple Car Play

Focus Area

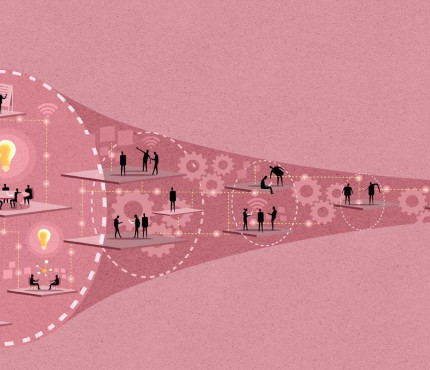

Vehicle owners are facing various challenges during the vehicle’s lifecycle and ‘waste’ a lot of their time on taking care of these matters. However today with the support of innovative technology and ‘internet of things’ devices, OEM companies are able to take over all activities the customer had to take care of and can even offer further premium services to ease the customer’s life and to generate follow-on sales.

Therefore, Four Principles’ focusses on implementing a unique customer experience throughout the vehicle lifecycle journey to establish a long-term relationship and to keep the customer loyal & satisfied, resulting in repeated purchases and increased follow-on sales.

Areas of waste often identified in the vehicle lifecycle management:

Transportation

Unnecessary transportation of the vehicles from one place to the other within the premises of the service center due to poor service operations such as lack of spare parts or elongated repair lead time which impact negatively the productivity of the employees

INVENTORY

Renting big warehouses/ large areas to store high volume of spare parts and new vehicles tie-up capital which cannot be utilized on short term in other activities and impact negatively the operational profit

Movement

Customers moving from one bank to the other to check for the best financial option or going through the insurance jungle to look for the optimal policy, all that creates additional uncertainty, unnecessary motion and ultimately dissatisfaction for the customer

Waiting / Delays

Delayed or non-provided vehicle service information to customer due to missing or uncomplete on real-time vehicle data that results in additional cost for the customer

Over-production / Over-Processing

Filling several documents manually which are entered on a later stage in the computer or not used at all only delays the process impacts negatively the employee’s productivity and the customer satisfaction

Defects

Activities that cause re-work, returns or adjustments, such as vehicle repairs which did not solve the customer complaint, incorrect documentation or wrongly customized offers that result in loss of customers

Space

Building facilities which are not seized on the available demand such as setting-up a huge service center with an overcapacity causing unnecessary costs

Lean Solutions

Lean focuses on increasing the portion of value adding activities in the value-chain and eliminating all activities which do not provide any value to the customer. Therefore, in a first step the voice of the customer is captured in order to understand the customer’s pain-points and the services and activities he expects from the service provider which would increase his satisfaction, loyalty and establish a long-term relationship to the brand. Based on this, the customer journey is completely re-designed with a bottom-up approach, including all employees from the shop floor level up to the senior management level resulting into the following changes:

Vehicle service logistics

Customers schedule through mobile application vehicle pick-up and & drop-off at their preferred location and time. Furthermore, replacement vehicles such as brand-new models can be booked for the duration of the service.

Service diagnostic

Mobile applications are connected with the customer’s vehicle & share in real-time data with the OEM which is utilized to provide the customer with accurate service needs on a timely manner. Service bookings are scheduled automatically based on customer preferences and vehicle service needs.

Vehicle services

Service appointment can be booked through mobile application by the customer and discounts are applied if vehicle services are booked at low traffic times. Vehicles services are tracked, and customers have real-time visibility on the repair/service status.

Continuous revenue engagement

Loyalty programs, integration of non-automotive partners, occasion-based interactions and customized offers are sent to the customers through social media and mobile applications.

Additionally, other premium services such as valet parking, vehicle cleaning are offered to the customer while visiting the branch

Payment options

Introduction of easy payment options through multiple platforms such as apple pay, online payment, beam, etc.

Customer usage experience

Implementation of machine learning & artificial intelligence features to feed-in driving habits and preferences which are utilized to improve further the customer usage experience

Tangible improvements

Lead time

- Reduction of vehicle repair lead-time from vehicle receiving by the service center until vehicle delivery to the customer for mechanical general jobs by 36% & periodic maintenance jobs by 5% by introducing job-card pulling system in the workshop & job-card scheduling based on actual workload

Quality

- Efficient utilization of workforce, available tools & equipment and repair stalls in the workshop resulted in an increase of mechanical technician productivity by 11% and service center capacity by 35%

- The new designed customer journey in the service center and in the sales area have improved the ‘Net Promoter Score’ (NPS) by 5% in the service area and by 25% in the sales area, through a bottom-up process re-engineering approach including staff members from the shop floor up to senior management level

Cost

- The biggest distributor of passenger vehicles in Saudi-Arabia saved in his biggest eleven 3S service centers in Saudi Arabia 19.4% of their total annual operating costs through establishing re-designed lean concepts in the areas of sales & after sales